FOWIC readies Bold Tern for next-gen wind turbines

Offshore wind turbines are getting taller and heavier, which means bigger challenges for their installation and maintenance. This has spurred Fred. Olsen Windcarrier (FOWIC) to add a new 1,600-ton crane to its jack-up vessel Bold Tern. This will make the heavy lift vessel ready for the future developments in the offshore wind industry.

Right now, the construction of the new crane is well underway, with plans for it to be transported to Keppel FELS in Singapore by the end of the year, where it will then be fitted onto Bold Tern. When it was built in 2013, it was designed to carry and lift the 3.6MW turbines in use at the time. Today, turbines have grown to be far larger and heavier, and plans for the installation of turbines up to 15MW are already in place. While this means greater efficiency for electricity generation, their size and weight present a serious challenge in terms of transportation, installation, and maintenance.

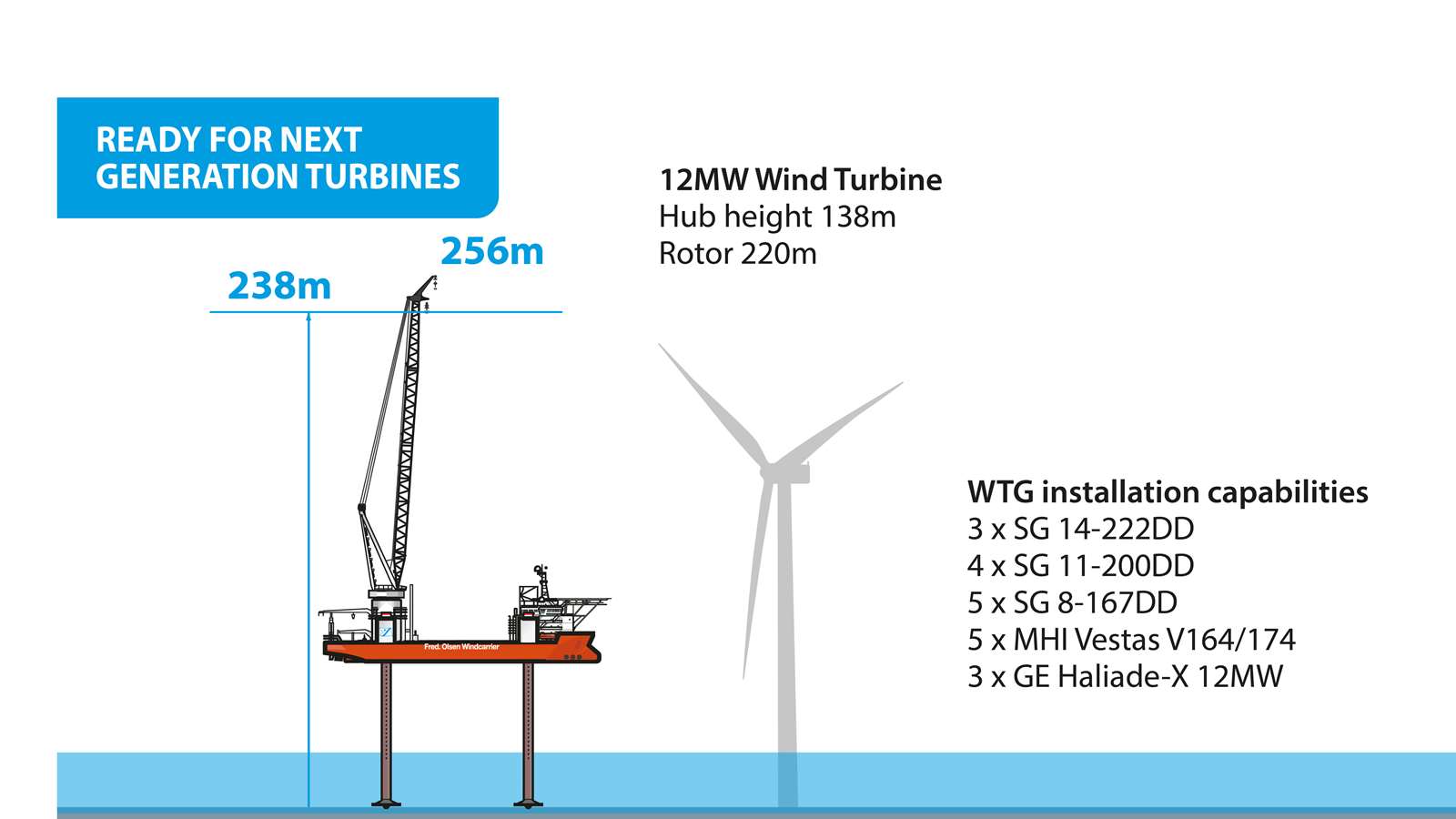

As a result, the decision was made to install a new 1600-ton LEC 65500 leg encircling crane on board Bold Tern. The new crane will be the highest in the market upon arrival, making the vessel one of the few in the world capable of installing the latest generation wind turbines. FOWIC has worked closely with Huisman, the crane supplier, to ensure the crane has the right specifications and features to meet the industry’s needs for many years to come.

Crane’s first task, wind turbines in Asia

Bold Tern’s first project with the new crane will be in Asia, where it is being upgraded. Also, the crane is being manufactured in Asia, which will minimise logistics costs and delivery times. Bold Tern, however, has already arrived at the shipyard. The reason for this is because before the crane can be installed, there are several other modifications to the vessel that need to be completed.

With a larger crane and bigger turbines on deck, Bold Tern will be heavier with a different centre of gravity, which will affect its floating stability and deck load capacity. To improve stability, the width of the vessel will be increased by sponsons, which will also enable it to carry larger turbines.

The problem is that all this will add to Bold Tern’s weight, which further affects its deck load capacity. To counteract this, changes will be made to the jacking system to increase jacking and preload capacity. This will allow jacking at heavier weights and more load to be placed on the seabed, as well as improving the vessel’s ability to remain jacked up in worsening weather.

There will also be improvements to the mooring system, giving Bold Tern the capability of being moored with its deck load, which increases operational flexibility. This will allow the customer to load out towers and nacelles jacked-up at one quayside position and then move to another quayside position for loading blades afloat.

You just read one of our premium articles free of charge

Register now to keep reading premium articles.